Creating a Recycling-Oriented Society

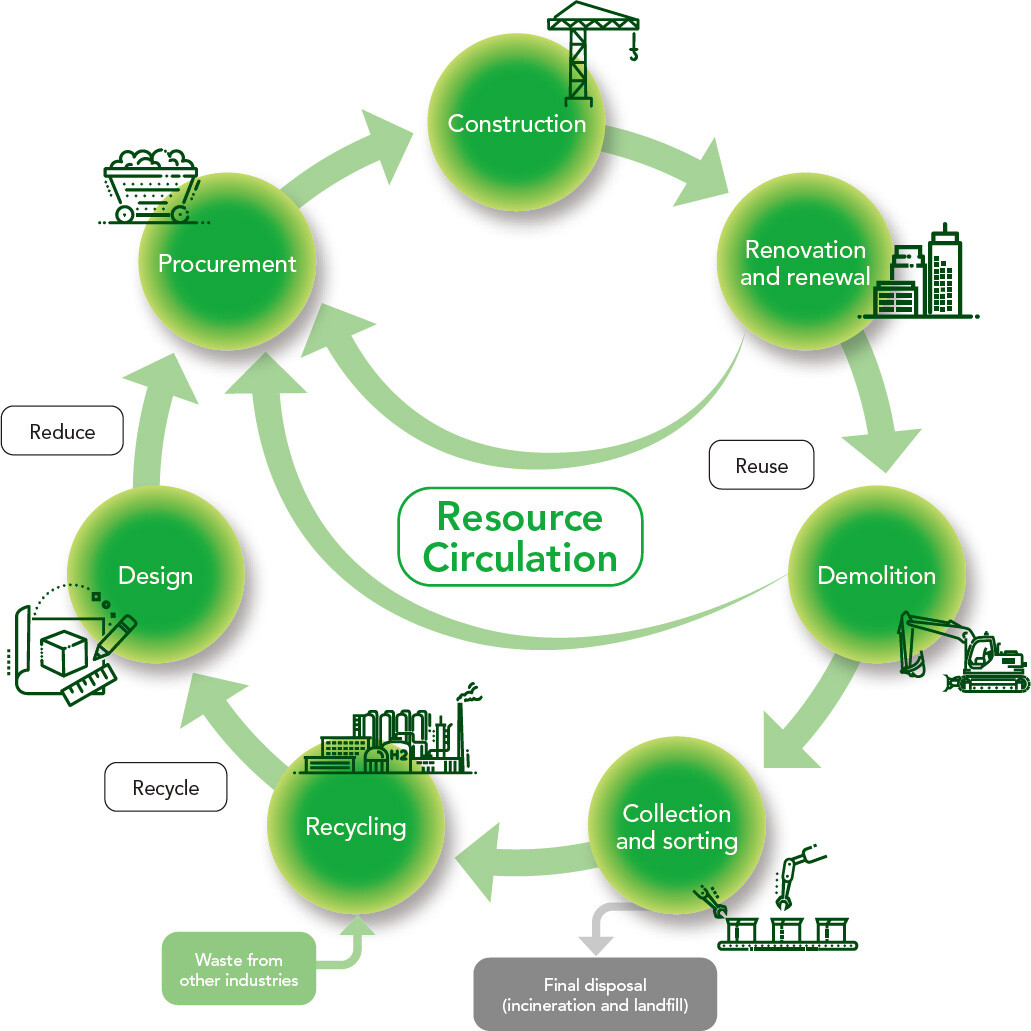

The Obayashi Group has formulated the Environmental Policy and been implementing initiatives throughout the supply chain to realize a decarbonized, recycling-oriented society that has respect for the natural world. For the realization of a recycling-oriented society, we are facilitating specific initiatives across our businesses, including recycling of materials and proper waste management through business activities.

Target for Realization of Recycling-oriented Society

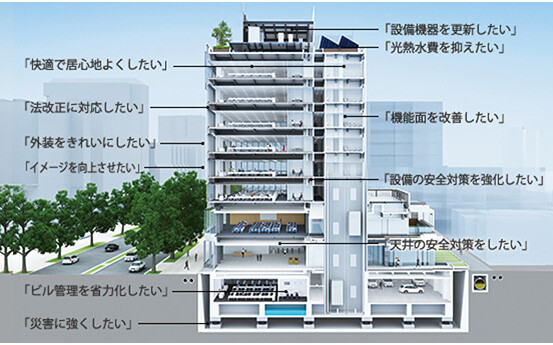

The Environmental Policy sets out efforts to reduce environmental impact through the Group's entire business activities for the realization of a recycling-oriented society. We believe that it is necessary to work to realize a recycling-oriented society by managing the entire supply chain and a building lifecycle (*1) in light of the 3Rs (*2). In order to reduce the final disposal of waste derived from the construction phase of the building lifecycle, we currently set the ratio of mixed waste to the total construction waste as a KPI and promote initiatives to achieve 3% or below. Further initiatives and targets are under review in light of societal circumstances and needs.

- *1 Building lifecycle

The lifecycle of buildings from their planning, designing, and construction to operation, maintenance, management, and demolition - *2 The 3Rs

Reduce, Reuse, and Recycle

Analysis of Current Situation and Issues Regarding Initiatives for Realization of Recycling-oriented Society

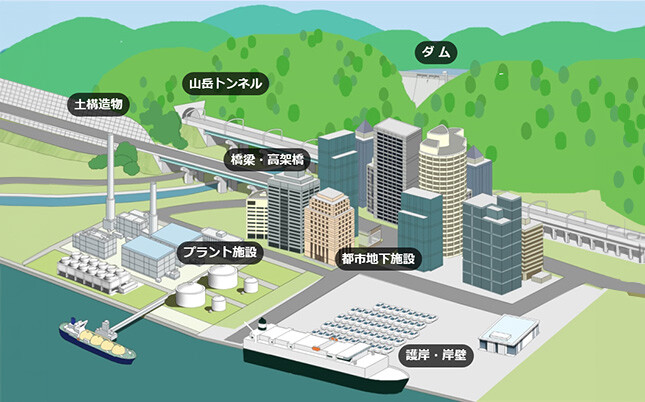

The Group has implemented initiatives for recycling resources primarily at the construction phase, such as zero waste activities as well as material development and practical application utilizing industrial by-products. Meanwhile, we see that our primary challenge is to increase initiatives covering the upstream (such as planning, design, and procurement) and the downstream (such as maintenance, management, and demolition) of our supply chain.

Realizing a Circular Economy to Achieve a Recycling-Oriented Society

In addition to the ongoing zero waste activities, we promote efficient and recycling-oriented use of resources to realize a circular economy that supports both a sustainable society and economic growth.

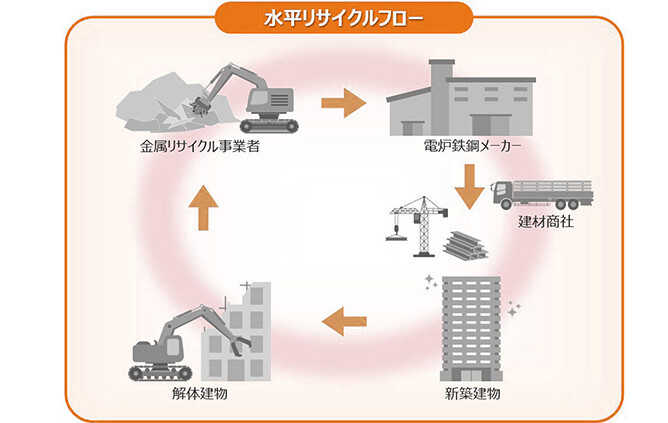

Promotion of Recycling of Construction Materials

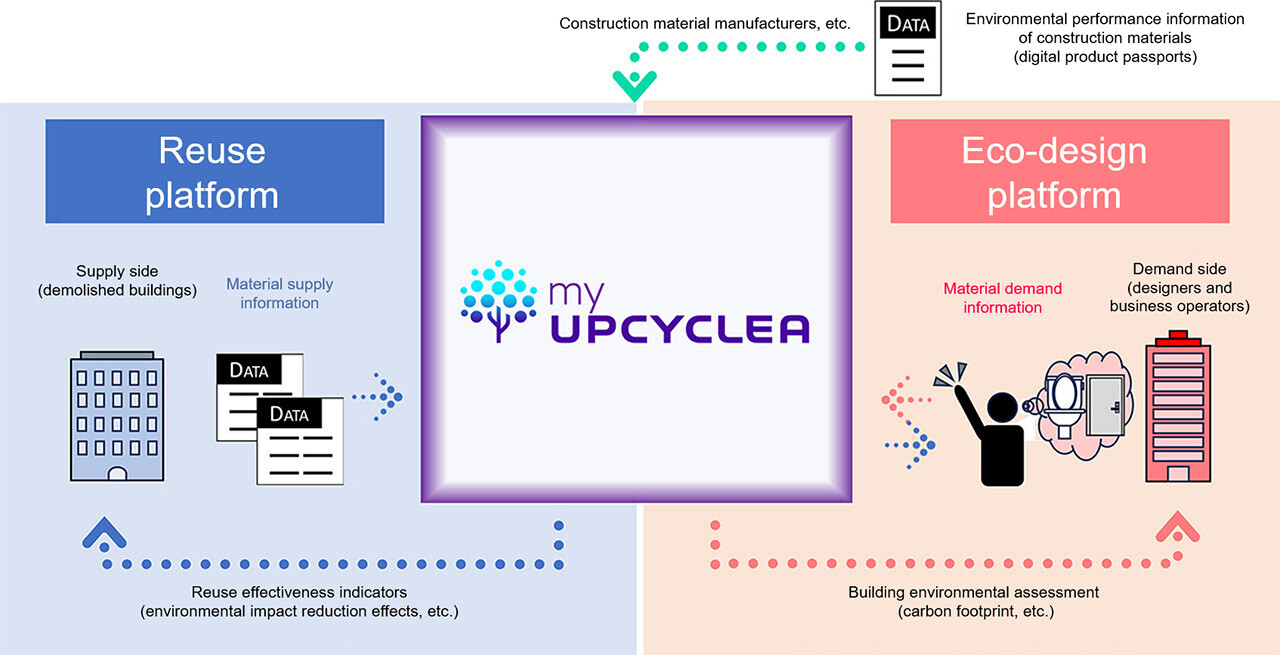

In order to not only recycle construction materials but also reuse interior materials and equipment, we have introduced myUpcyclea, a resource recycling data platform operated by Upcyclea. This platform visualizes the environmental performance of construction materials and reusability of materials arising from construction demolition, helping us facilitate recycling of construction materials.

Waste Management

Obayashi is also working to reduce the ratio of final disposal and to promote horizontal recycling. The Group has introduced electronic manifest at all offices since 2006 to strengthen waste management.

Building Structure Reuse

In construction of a new laboratory building of the Obayashi Corporation Technology Research Institute, we reused steel-frame and concrete structural materials from the demolished building. This was Japan's first initiative of its kind (*3) and received the Ministry of Land, Infrastructure, Transport and Tourism's Prize at the FY2025 3Rs (Reduce, Reuse, and Recycle) Promotion Awards.

- *3 Based on our research (June 2024)

Post-Demolition Steel-Frame and Concrete Structural Components Reused in a New Building for the First Time in Japan

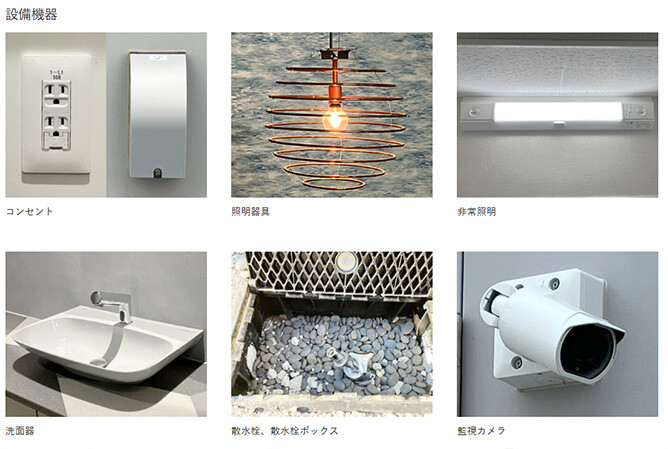

Reuse of Building Equipment and Construction Materials

We are reusing approximately 180 items across 30 categories of building equipment and construction materials, originally used in the Panasonic Group Pavilion, "The Land of NOMO," at the Expo 2025 Osaka, Kansai, Japan, for the construction of a new laboratory building at the Obayashi Corporation Technology Research Institute.

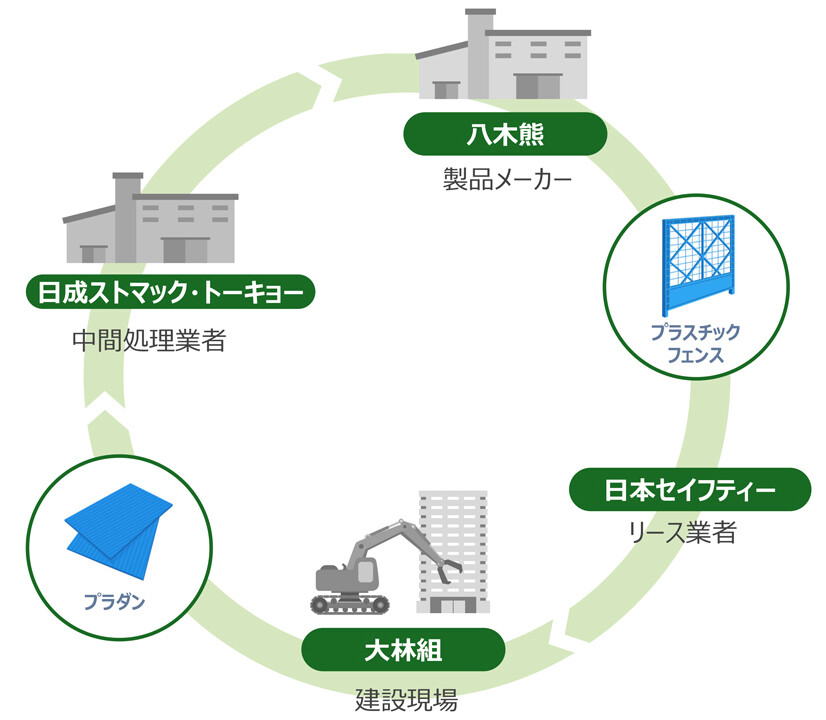

Recycling of Temporary Construction Materials

In collaboration with product manufacturers, intermediate processors, and leasing companies, we recycle plastic corrugated boards discarded at Obayashi Corporation construction sites into construction fences, which are then used as temporary enclosure at the construction site of a new laboratory building for our Technology Research Institute.

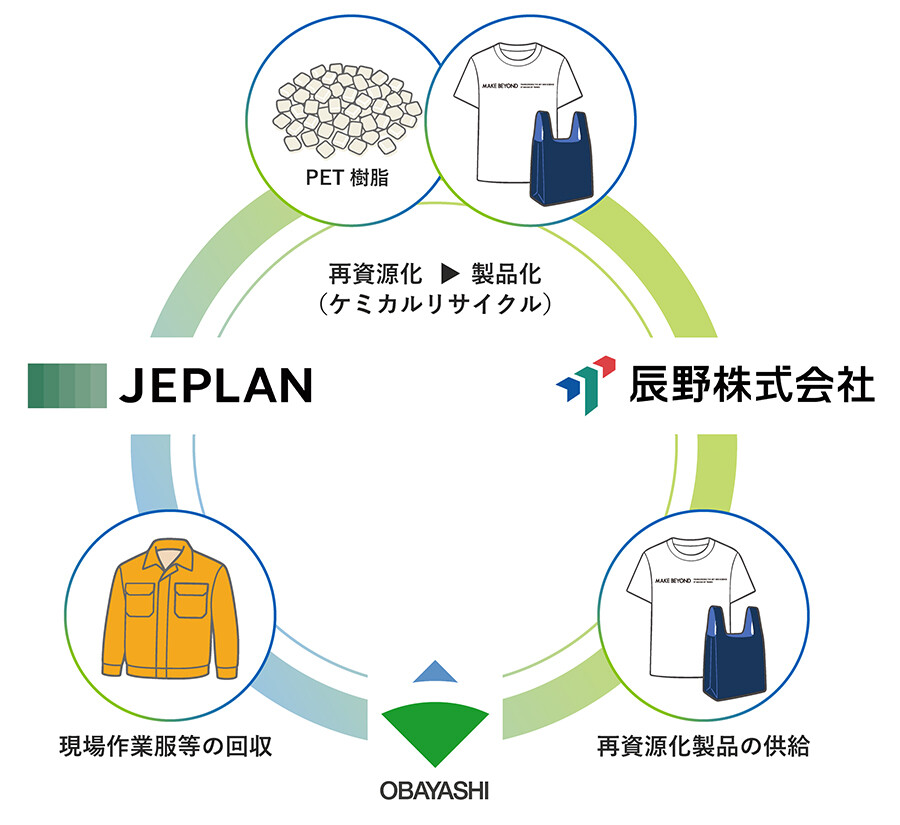

Large-Scale Recycling of Workwear

We launched a large-scale initiative to collect used pieces of workwear from Obayashi Corporation's construction site offices and business locations across Japan, and to recycle them in collaboration with a chemical recycling company and a product manufacturer.

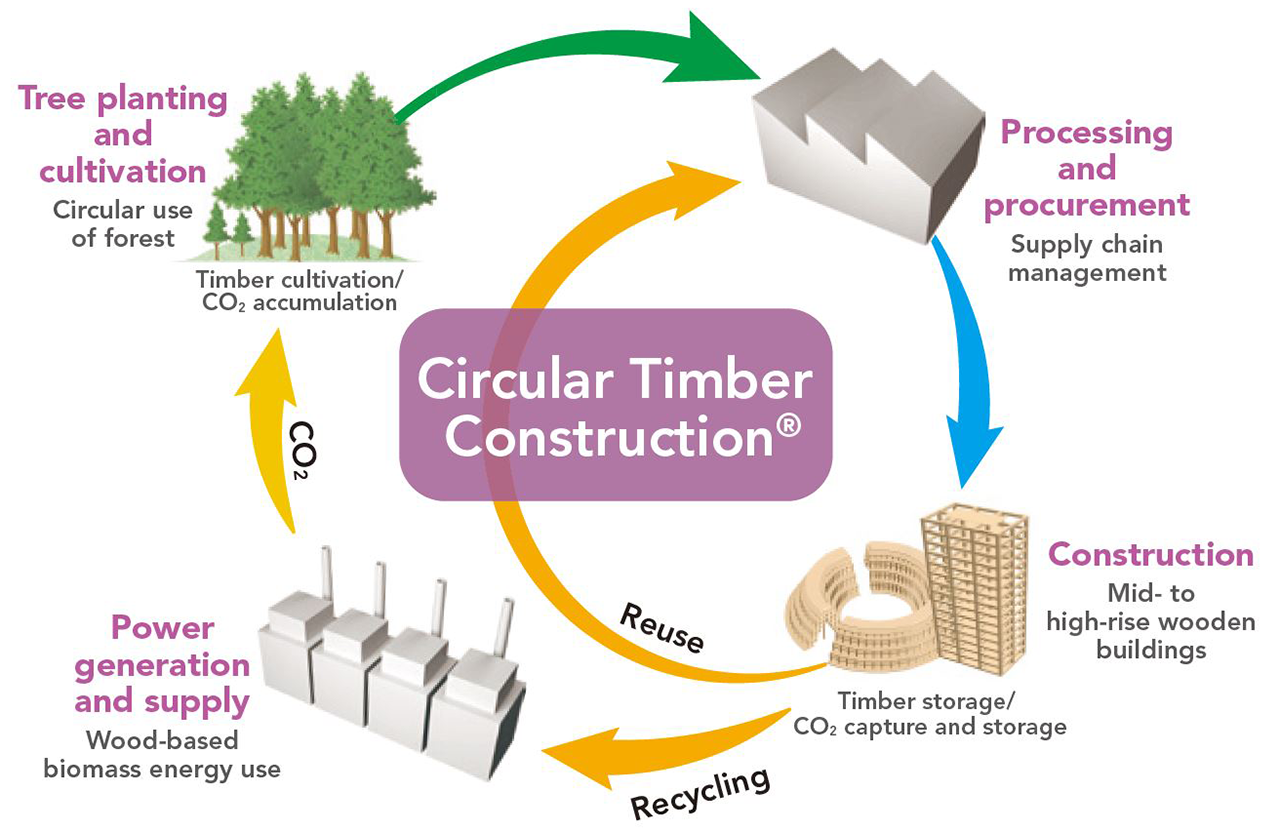

Circular Timber Construction™

Going beyond the promotion of wooden structures and interiors, the Obayashi Group draws on its past experience, expertise, and knowledge in forestry to promote a complete and sustainable cycle for domestic timber. This cycle encompasses operations upstream (tree planting and cultivation), midstream (processing and procurement), downstream (construction), and beyond (power generation and supply). Through this initiative, we aim to use sustainable forest resources and to realize a society that respects the natural world.

Traceability Survey

In response to growing public concern about violations of human rights and environmental destruction in supply chains, we have been conducting traceability surveys since 2021 on imported timber materials and solar panel materials, which are considered to be at high risk of human rights violations.

Water and Forest Resource Risks

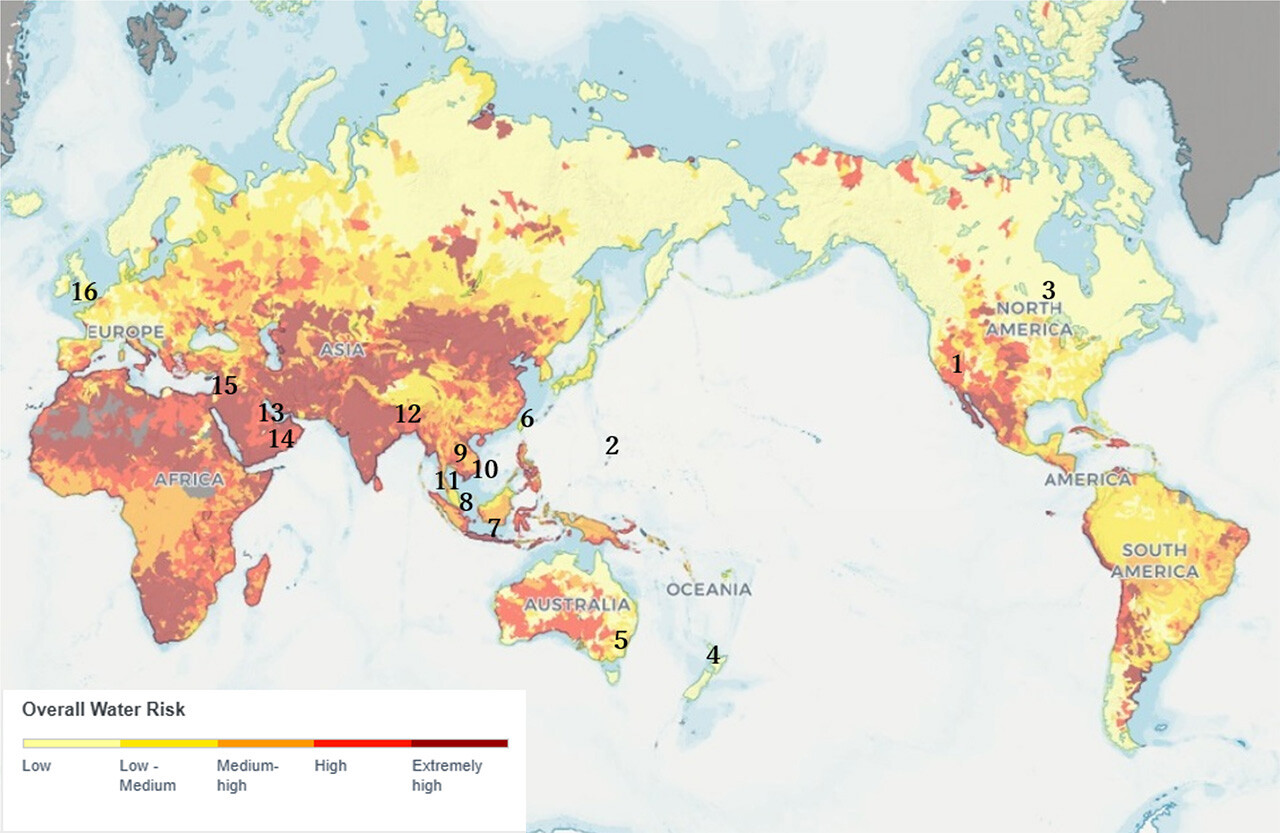

Water resources and forest resources are highlighted as challenges in resource recycling facing the construction industry. Our business activities utilize timber and water, and water and forests are closely related to the construction industry. Although the consumption is smaller than that of other materials such as steel and cement, we position timber as one of important materials from viewpoints of conserving biodiversity and respecting human rights, as well as its potential as a renewable material. In Japan, water is abundant in quantity (*4) and therefore we focus on risks in quality (*5), while there are water resource risks in quality and/or quantity inherent in other parts of the world. Based on the understanding of these aspects, we will make efforts to minimize the risks in accordance with laws and regulations and according to needs in local communities. In addition, since timber, supplied from forests, and water, supplied from rivers and groundwater, are connected with the realization of not only a recycling-oriented society but also a decarbonized society and a society that respects the natural world, we are conducting business by developing consumption plans suited for each community taking into account the risks.

- *4 Risks in quantity

Meaning the amount of available water resources (Ministry of Land, Infrastructure, Transport and Tourism(Available only in Japanese)) - *5 Risks in quality

Meaning water pollution, contamination, etc.

- *6 Aqueduct Water Risk Atlas

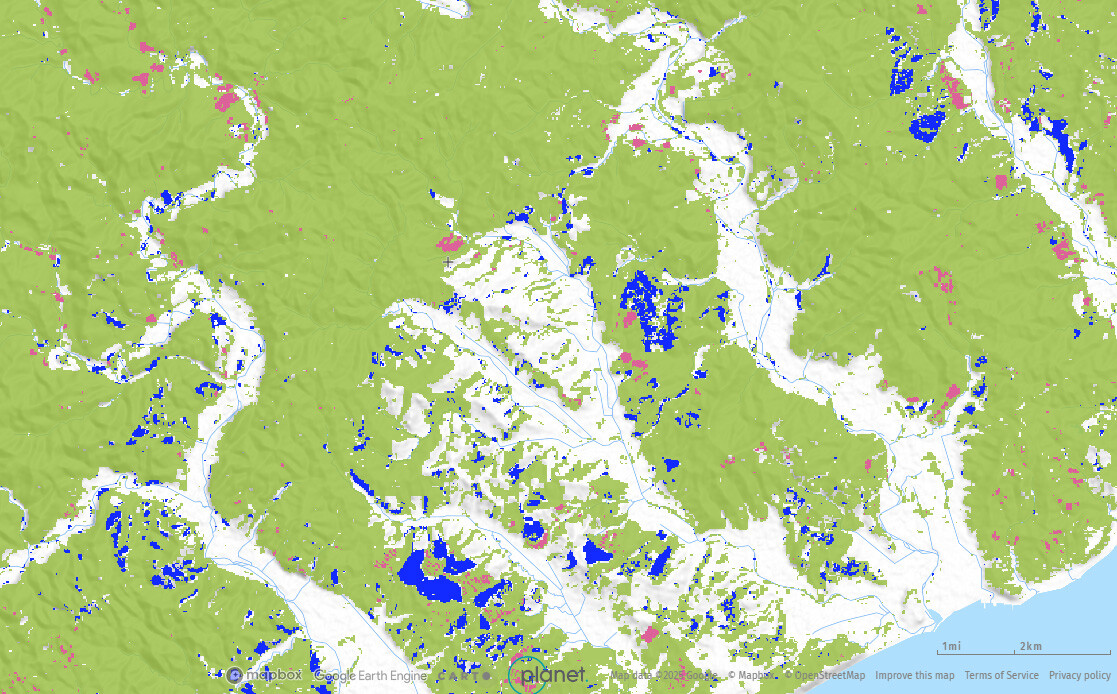

Tool to evaluate and visualize water risk in the world - *7 Global Forest Watch

Provides information on forest cover, land use, and biodiversity sites to identify risks of deforestation and land conversion

Going Forward

At present, the ratio of mixed waste to the total construction waste is set as a KPI. To realize a recycling-oriented society, it is important to recycle resources throughout the supply chain. The roadmap is now under review according to the implementation status and social conditions.